Guide to Efficient Storm Window Replacement Options

Introduction: Why Storm Window Replacement Matters (Plus the Outline)

Windows do far more than frame a view; they set the tone for comfort, quiet, and energy use inside your home. When older primary windows meet changing seasons, storm windows act like a practical overcoat—slowing heat loss, taming drafts, and making rooms feel calmer. Replacing tired storm units or adding new ones is a straightforward way to boost energy performance without tearing out existing windows. For households that value preservation, cost control, and comfort, storm windows are a well-regarded upgrade that blends science with sensibility.

Before we dive into details, here is the outline we will follow so you can jump to what matters most:

– Section 1: Big-picture benefits and how storm windows fit into a home’s efficiency strategy.

– Section 2: Energy metrics demystified—U-factor, SHGC, air leakage, and low-e coatings—plus why they matter.

– Section 3: Replacement choices explained—materials, configurations, interior vs. exterior, and cost ranges.

– Section 4: Installation steps, measurement tips, sealing methods, and common mistakes to avoid.

– Section 5: Realistic savings, payback timelines, maintenance routines, incentives, and a concise conclusion tailored to homeowners.

What makes storm window replacement especially attractive is its combination of impact and restraint. Instead of a full window swap, you keep the character and structure of your primary windows while adding a protective, insulating layer. Studies and field data consistently show that storm units can reduce infiltration and conductive heat loss, often making single-pane or leaky assemblies perform closer to modern double-pane equivalents. You may also notice quieter interiors, reduced dust, and less condensation, especially when the fit and seal are dialed in. And while windows can be a home’s trickiest energy culprits, storms offer a budget-friendly counterpunch that you can complete with standard tools and some mindful prep. By the end of this guide, you’ll have the knowledge to choose materials, read performance labels with confidence, and install with the kind of care that leads to durable, efficient results.

Energy Performance 101: U-Factor, SHGC, Air Leakage, and Low-E for Storms

Energy metrics translate a window’s behavior into numbers you can compare. Start with U-factor, which measures heat transfer; lower values mean better insulating performance. A typical older single-pane window can have an assembly U-factor around 1.00 Btu/hr·ft²·°F, while adding a well-fitted storm window may bring the effective U-factor for the window-plus-storm assembly closer to roughly 0.50–0.60, and even lower with a low-emissivity (low-e) coating. Exact performance depends on fit, frame material, glass type, and installation quality, so consider listed values as ballpark guides rather than promises.

The Solar Heat Gain Coefficient (SHGC) indicates how much solar energy enters as heat; values range from 0 to 1. In cooling-dominant climates, aim for a lower SHGC (for example, around 0.25–0.40) to reduce unwanted heat gain. In heating-dominant areas, a moderate SHGC (for example, around 0.35–0.55) can help capture winter sun while the storm unit reduces conductive loss. Keep in mind that orientation matters: south-facing windows may benefit from seasonal solar gain, while west-facing windows often need more shading due to low-angle afternoon sun. If your storm window offers glazing options, match SHGC to your climate and room orientation rather than applying a one-size-fits-all approach.

Air leakage, often expressed in cubic feet per minute per square foot (cfm/ft²), reveals how much air sneaks through joints and seams. A secure, gasketed storm window can significantly reduce infiltration compared to a loose or warped unit. Many homeowners notice a meaningful comfort improvement simply by curbing drafts around frames. When combined with careful weatherstripping on the primary window, a new storm can cut perceived drafts dramatically and stabilize indoor temperatures room to room.

Low-e coatings are ultra-thin metallic layers that reflect infrared energy while allowing visible light to pass through. On a storm window, low-e can improve winter performance by reflecting heat back indoors and can moderate radiant asymmetry that makes you feel chilly near glass. In warm seasons, certain low-e formulations help manage solar gain. While low-e storms may cost more than clear glass versions, the comfort boost and potential energy savings often justify the premium in climates with pronounced temperature swings.

Putting it together: a thoughtfully selected storm window balances U-factor, SHGC, and air leakage to suit your climate and orientation. The payoff appears as steadier indoor temperatures, quieter rooms, and more predictable energy bills. The key is alignment—choose metrics based on how your spaces behave throughout the year, and your windows will feel like a cooperative part of your home’s envelope rather than a weak link.

Replacement Options: Materials, Configurations, and Cost Considerations

Storm windows come in a range of materials and styles, each offering trade-offs in durability, maintenance, and appearance. Aluminum frames are common thanks to their strength, slim sightlines, and resistance to weather; they are lightweight and straightforward to install. Wood frames add warmth and are easy to repair or refinish, which appeals to those maintaining historic aesthetics, though they require periodic sealing or painting. Vinyl frames are low-maintenance and resist moisture, but profiles can be bulkier, and color choices may be limited compared with wood’s finish versatility.

When deciding between exterior and interior storms, consider exposure, access, and desired appearance. Exterior storm windows (including two-track or triple-track designs) mount to the outside and provide a robust barrier against wind and rain. They often include operable sashes and screens, offering seasonal flexibility. Interior panels, which can be magnetic, compression-fit, or framed insert systems, attach on the room side of the primary window. They are convenient for upper stories, rentals, or locations where exterior changes are restricted, and they can deliver tight air seals with minimal visual change from the street.

Glazing choices add another layer of customization. Clear glass offers durability and clarity; tempered glass increases safety; acrylic or polycarbonate reduces weight and risk of shattering but may scratch more easily. Low-e glass enhances thermal performance and comfort near the window. Pair glazing with appropriate weatherstripping—foam, pile, or gasket materials—to tune the seal. Thoughtful selection of fasteners, corner keys, and frame joinery also contributes to longevity and reduced air leakage.

Costs vary by region, size, and specifications, but broad ranges help with planning:

– Exterior aluminum storms with clear glass: roughly moderate in price, often accessible for DIY.

– Low-e exterior storms: a step up in cost, reflecting upgraded glazing.

– Interior panels: can be economical, especially for straightforward openings or temporary needs.

– Custom shapes or large openings: expect higher pricing due to fabrication complexity.

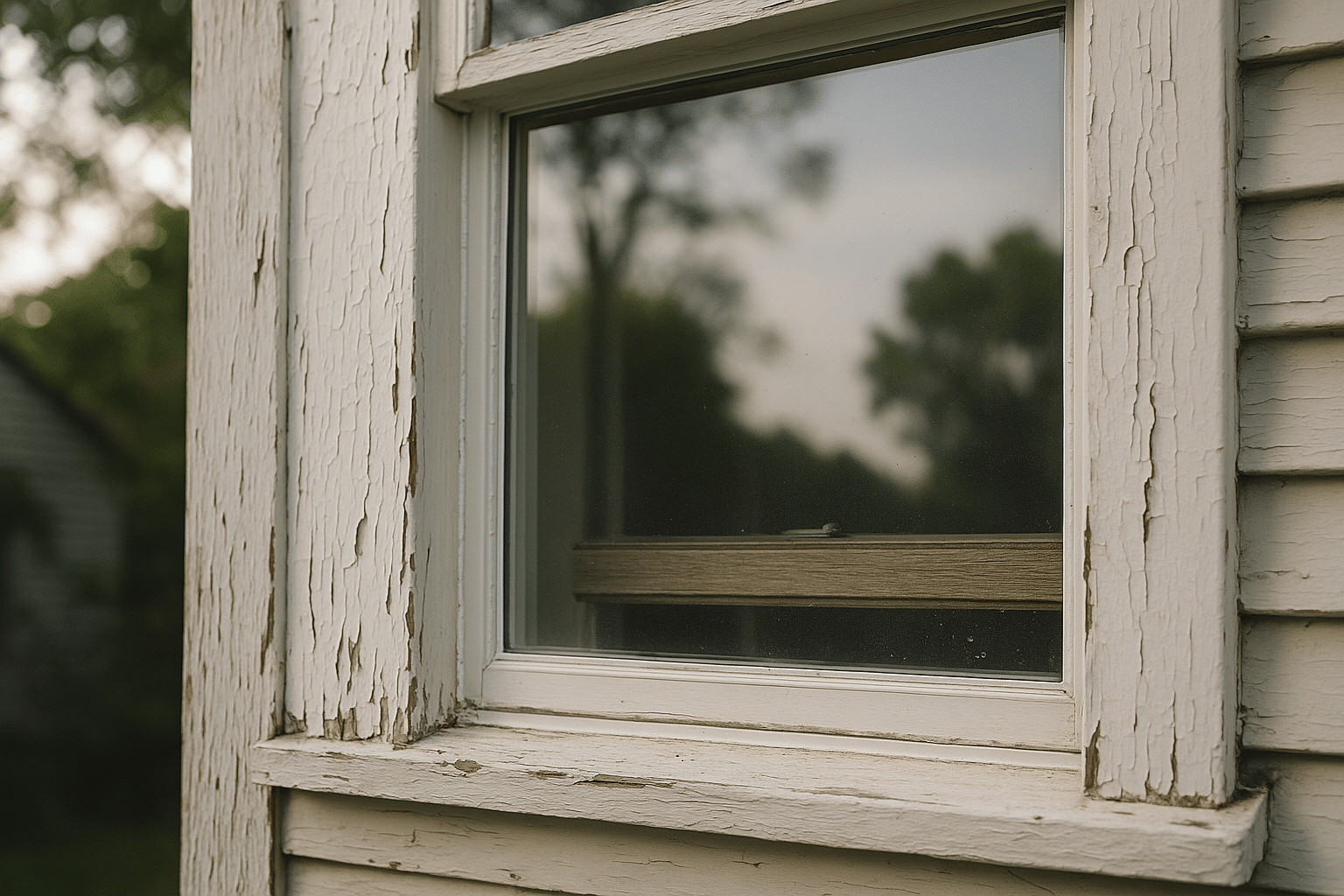

Beyond sticker price, consider value over time. Durable frames, reliable seals, and low-e glazing can reduce energy use and maintenance calls, potentially offering payback in a handful of heating or cooling seasons depending on climate and utility rates. If you’re preserving original wood windows, a high-quality storm acts as a protective shield, slowing weathering and deferring costly repairs. In short, the right replacement option balances performance, aesthetics, installation practicality, and long-term costs for your specific home and climate.

Installation Guide: Measuring, Preparing, Sealing, and Finishing

Good installation unlocks the performance you pay for. Begin with careful measurement. Check width and height in three places (top, middle, bottom for width; left, center, right for height), and note the smallest dimension. Assess squareness by measuring diagonals; if they differ, the opening is out of square. Document sill slope and trim conditions, and photograph details you might forget mid-project. For exterior units, inspect the primary window’s paint and putty, confirm operability, and decide where the storm will land relative to exterior trim for both weather protection and aesthetics.

Surface preparation is essential. Clean the mounting surfaces, remove loose paint, and repair rot before proceeding. If gaps exceed about 1/4 inch, consider backer rod behind sealant to provide a firm backing and reduce sealant waste. Use a high-quality exterior-grade sealant appropriate for the materials at hand. Pre-drill frame holes to prevent splitting, especially for wood. Dry-fit the storm window to verify alignment, confirm that the sill angle matches, and mark fastener locations that avoid cracking corners or interfering with existing hardware.

When fastening, start at the top center, then set corners, and finally fill in perimeter screws while verifying that the frame remains square and not racked. Maintain drainage paths; do not block factory weep holes. A minimal, continuous bead of sealant at the head and jambs is typical, while the sill line may need selective sealing to allow incidental moisture to exit. If needed, add a drip cap above the head to shed rain beyond the frame face. For interior panels, ensure the compression or magnetic seal is continuous, even, and not over-tightened, which can warp frames or stress glazing.

Common mistakes to avoid:

– Over-caulking the sill and trapping water, leading to rot or fogging.

– Driving fasteners too close to corners, causing cracks or distortion.

– Ignoring out-of-square openings, which creates gaps and rattles.

– Covering ventilation or egress clearances where required by code.

After installation, operate sashes and screens to confirm smooth travel. Inspect at dusk with interior lights on; light leaks mark gaps that need attention. From a comfort perspective, the difference is noticeable on windy days when drafts soften to a hush. A measured approach—careful layout, gentle persuasion rather than force, and attention to drainage—turns a simple project into a durable upgrade that feels professionally executed.

Efficiency Gains, Payback, Maintenance, Incentives, and Conclusion

Windows influence comfort and costs more than most homeowners realize. In many houses, windows account for a meaningful slice of heating and cooling loads due to conduction through glass and frames plus air leakage around operable parts. By tightening the fit and improving thermal resistance, storm windows help mitigate both issues. Field studies and utility program data indicate that adding low-e storms to leaky single-pane units can reduce window-related heat loss substantially and may trim whole-home heating energy by a modest but noticeable margin, especially in colder climates. In cooling-dominant regions, choosing a lower SHGC and ensuring tight seals can also reduce air conditioning demand by curbing solar gain and infiltration.

Estimating payback requires local numbers, but a simple framework helps:

– Annual energy savings depend on climate severity, fuel costs, and baseline window condition.

– Upfront costs hinge on size, glazing choice, and whether you self-install or hire a pro.

– Comfort improvements—less draft, steadier temperatures, reduced noise—add non-monetary value that owners consistently report as significant.

As a rough planning guide, many projects recoup costs over several heating seasons when replacing very leaky or deteriorated storms, with quicker returns in colder regions and slower returns where winters are mild. Beyond energy, storms can extend the life of primary windows by shielding them from rain, UV, and abrasion, reducing repainting frequency and sash repairs. Interior comfort also improves near the glass, where radiant asymmetry can make you feel chilled even when the thermostat reads warm.

Maintenance is straightforward. Clean tracks and weep holes each season to preserve drainage. Inspect sealant lines and touch up where movement or UV exposure opened hairline gaps. Lubricate moving parts sparingly, wipe glazing with non-abrasive cleaners, and replace worn weatherstripping before drafts creep back. For interior panels, check compression or magnetic seals annually and store removable inserts flat, protected from scratches.

Check local incentives or tax credits that may apply to energy-efficient window upgrades, including storms; programs vary and often require documented performance ratings and proof of purchase. If you plan phased work, prioritize rooms with the strongest drafts or the most exposure to wind and sun, then proceed systematically. You can also pair storms with simple envelope improvements—attic air sealing, targeted insulation, or shading—to amplify results.

Conclusion and next steps: For homeowners who want practical, low-disruption efficiency gains, storm window replacement sits at a sweet spot of impact, cost, and preservation. Choose materials and glazing that fit your climate and architecture, install with an eye for drainage and air sealing, and keep a short maintenance checklist. The reward is a home that feels calmer when the weather shouts, with bills that trend steadier and windows that stand their ground for years to come.